Energy storage battery assembly automation

Huiyao Laser Semi-Automated Energy Storage Prismatic Battery

It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding

5 FAQs about [Energy storage battery assembly automation]

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

What is a battery assembly solution?

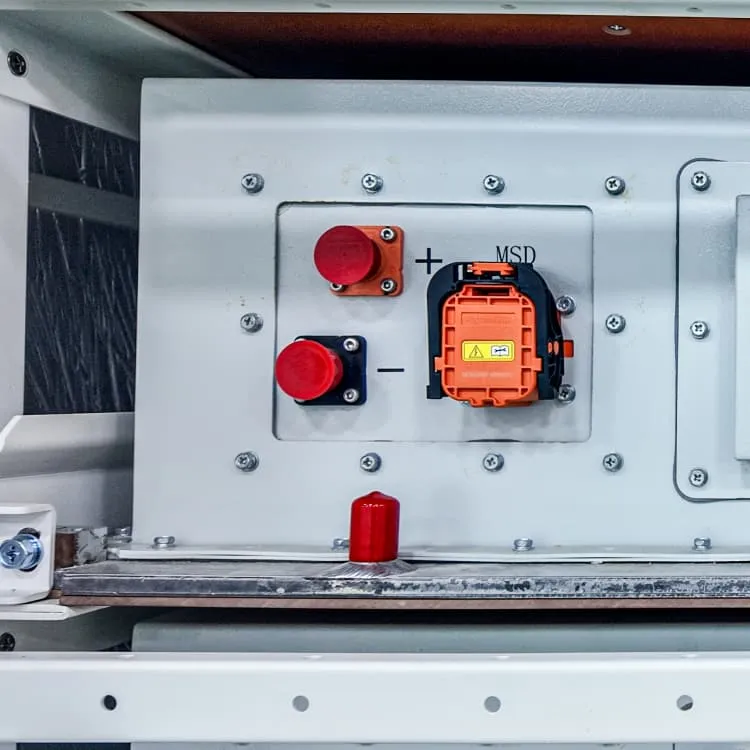

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

What is a battery energy storage system?

A battery energy storage system, or BESS, is a system that uses batteries to store energy for later use. With the advent of this technology, energy usage could see a complete transformation; allowing access to energy sources when needed while reducing our dependence on traditional energy sources from fossil fuels.

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What are the technical parameters of intelligent battery pack?

Intelligent battery pack finished product handling and packaging system. 3: Technical Parameters: Total production line length: 16 meters. Production capacity: Up to X battery packs per hour (customizable). Precision level: ±0.1mm positioning accuracy. Processing efficiency: 99.5% uptime.

More information

- South Korea s wind and solar power system

- What are the types of energy storage equipment specifications

- 5G communication base station EMS energy storage cabinets

- China s 5G base station electricity costs

- Sweden 5G communication base station energy storage system

- Inverter power generation advanced AC

- Korean outdoor communication power supply BESS

- Ecuadorian communication base station wind and solar hybrid power generation

- Swaziland Solar Energy Storage Product Introduction

- Kyrgyzstan s new local outdoor power supply

- Installation of photovoltaic solar panels on the balcony of my home

- Cambodia power inverter price

- Australia BESS photovoltaic folding container wholesale

- Photovoltaic energy storage 50 kWh

- Malaysia three-phase inverter

- Nicaragua Solar Photovoltaic Curtain Wall Design

- 12v motor inverter to 220v

- How much area does a 10MW energy storage power station require

- Recommended suppliers of communication base station power modules

- Monaco flywheel energy storage photovoltaic power generation efficiency

- Liberia Power Plant Energy Storage Project

- Estonian flow battery manufacturer

- Base station energy management system installed on rooftop in Costa Rica

- Small outdoor battery plus inverter

- Maximum charge and discharge rate of energy storage system

- Zimbabwe Grid-Side Energy Storage Lithium Battery