Can lithium battery packs be made into split compartments

Understanding Lithium Battery Pack Enclosure Design for Electric

Let''s dive into the essentials of designing these crucial battery enclosures. What''s a Lithium Battery Pack and Its Casing? A typical Li-ion battery pack consists of: • The Enclosure:

Safe to use a W-Split Parallel cable to connect 3 x 48v 9AH batteries

Lithium batteries (or almost any batteries) will make a hell of a nasty surge when two packs are connected, if the charge levels are different. Depending on how good the controller is, this

6 FAQs about [Can lithium battery packs be made into split compartments ]

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is a Li-ion battery pack?

A typical Li-ion battery pack consists of: • The Enclosure: Usually split into an upper cover and a lower case (or tray). • Li-ion Cells: The core energy storage units. • High-Voltage (HV) Components: Connectors, busbars, etc., for power transfer.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

What is a split pack electric vehicle battery?

EVs have split battery packs to help with charging compatibility and eliminate the need for a voltage booster. All electric vehicles have big battery packs that can hold dozens of kilowatt hours of electricity, which are required to power their powerful traction motors for hundreds of miles.

How a lithium ion battery is made?

The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries. The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap.

More information

- Palau Energy Storage System Peak-Valley Arbitrage Partner

- Energy Storage Container Policies

- Kyrgyzstan stacked energy storage batteries

- Chad imported energy storage cabinet battery price

- Can a sine wave inverter power a home

- Micronesia Customized Power Generation Container

- Home solar system manufacturers

- Energy storage battery pack 48v

- Mobile outdoor base station control cabinet manufacturer

- Office building installed with solar panels

- What is an inverter manufacturer

- Energy storage battery cabinet 100 degrees

- Huawei Portugal Energy Storage System Integrated Warehouse

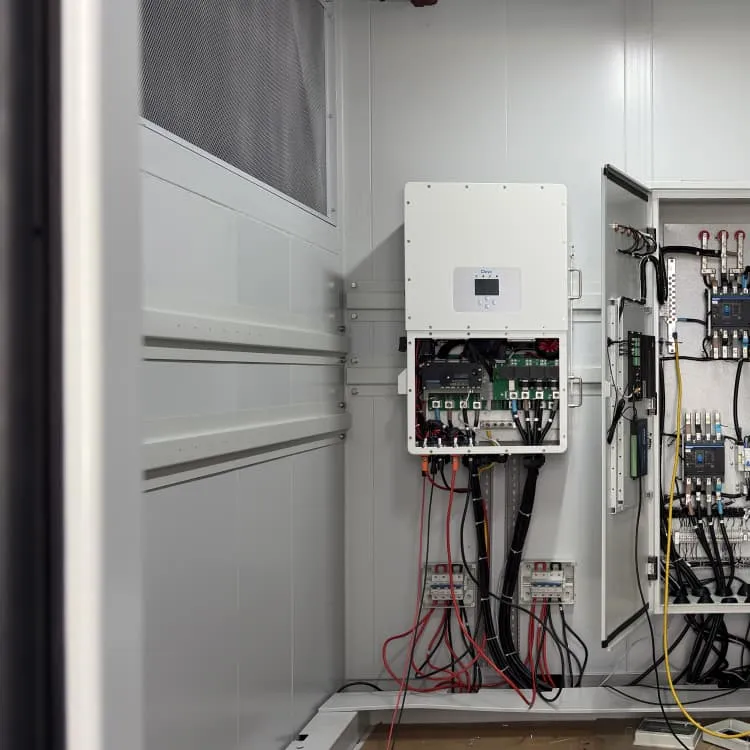

- Off-grid and grid-connected energy storage cabinet

- Bulgaria s commercial and industrial energy storage photovoltaics

- Is there a 12v to 220v inverter in Malta

- How much is the grid-connected power of the communication base station inverter

- Solar panels 50 square meters

- New battery cabinets launched in Denmark

- East Timor Single Battery Energy Storage

- Solar Photovoltaic Power Generation Services

- Photovoltaic solar power generation system in Zimbabwe

- How much does a battery cabinet plus a mobile power supply cost

- Photovoltaic energy storage device in Burundi

- Single-phase off-grid photovoltaic inverter

- Energy storage cabinet container