Amorphous inverter custom high frequency

Unlocking the Potential of Amorphous C Cores for High-Frequency

In this article, we will delve into the characteristics, benefits, and applications of amorphous C cores in high-frequency circuits and explore how they are revolutionizing various industries.

Custom high performance amorphous and nanocrystalline multi

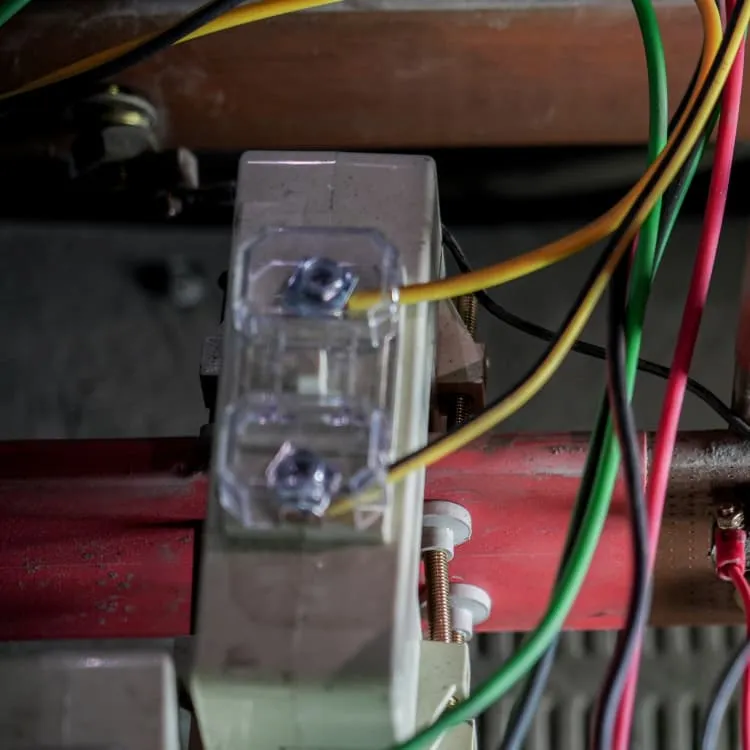

Amorphous C core is design for high power usage, C type core is easy to install, easy to winding copper wire.High saturation flux density, low core loss. Suitable for solar inverter filter, medium

high frequency inverter welding transformer inductor toroidal

high frequency inverter welding transformer inductor toroidal ferrite amorphous core Amorphous and nanocrystalline technology is a very important technology in modern magnetic materials,

Amorphous Transformer | The Secret to High-Efficiency Inverters

The efficiency of this core is very high, it can operate at high frequencies, and it can handle up to 5kW with just one core having a diameter of 64mm. If you like my video, give me a cup...

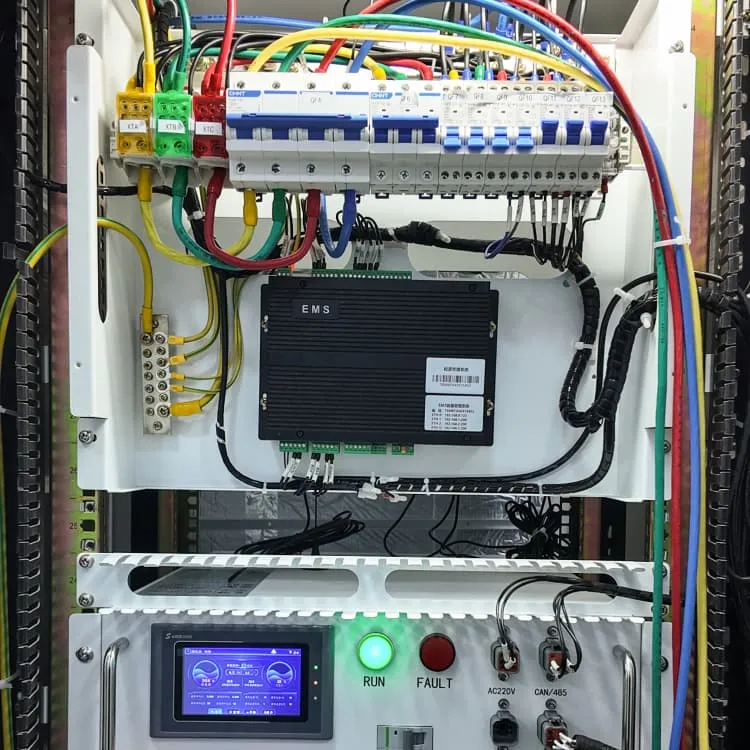

Amorphous C Core in 1K101 for PV Inverter, High Frequency

Amorphous core are with high saturate induction, rectangular form, with excellent anti-bias current ability, low core loss excellent stability.Mainly use for PV inverter, high frequency large power

6 FAQs about [Amorphous inverter custom high frequency]

What are amorphous magnetic cores?

Amorphous magnetic cores have superior magnetic characteristics, such as lower core loss, when compared with conventional crystalline magnetic materials. These cores can offer superior design alternative when used as the core material in the following components:

Why does amorphous magnetic metal have high permeability?

Amorphous magnetic metal has high permeability due to no crystalline magnetic anisotropy. Amorphous magnetic cores have superior magnetic characteristics, such as lower core loss, when compared with conventional crystalline magnetic materials.

Which amorphous materials are used in power inductor applications?

Nickel–iron alloy (NiFe) cores are commonly used in power inductor applications as they ofer good coercivity compared to ferrites and have higher flux densities as well. The chart in Figure 2 shows that amorphous materials have a good mixture of coercivity and saturation flux density.

Are amorphous cores better?

The Amorphous core will tend to be less expensive, and have lower losses, smaller physical size, better heat dissipation, and are mechanically rugged. The will have lower power loss and smaller however cost will be slightly higher.

What are amorphous metal C-cores?

Amorphous metal C-cores allow for operation at higher frequencies at the same flux level. Where traditional steel cores need to operate at increasingly lower flux densities as the frequency increases. In order to compensate for running at lower flux densities significantly more material is needed.

What is a microlite 100 amorphous toroidal core?

These cores are ideal candidates for PFC boost inductor applications in power supply ranges from 300 to 6kW (for higher power design see Powerlite). Microlite 100 μ are tape wound amorphous toroidal cores with a small gap, which allows the core to achieve permeabilities less than 245.

More information

- The smallest and lightest outdoor power supply

- Swedish Telecom Base Station Wind and Solar Complementary Manufacturer

- Characteristics of Western European Power Plants

- The company focuses on the layout of photovoltaic inverters

- Paraguay grid-side energy storage investment

- Somali Mobile Company s communication base station flow battery

- UAE export energy storage battery manufacturers

- Sodium battery energy storage and power generation

- Commercial photovoltaic panels wholesale factory direct sales

- Photovoltaic panels in El Salvador

- Home installation of solar panels

- 50kw centralized inverter

- PV panel inverter brand

- Somaliland energy storage power supply price

- General photovoltaic panel appearance model and specifications

- Wind power supply for communication base stations in Mongolia

- Ireland hybrid energy storage project investment

- Container energy storage cabinet production equipment manufacturers

- All-vanadium batteries and energy storage

- Argentina vanadium flow battery

- Is there a 1500-watt solar panel

- Brand of monocrystalline photovoltaic panels in El Salvador

- Rural solar base station battery

- How to pair solar panels with a 6kw inverter

- How much electricity can a 230ah battery store

- Traditional energy storage devices