Flywheel energy storage price electrical design

Development of a High Specific Energy Flywheel Module,

a rapidly spinning wheel - with 50 times the Storage capacity of a lead-acid battery As the flywheel is discharged and spun down, the stored rotational energy is transferred back into electrical

6 FAQs about [Flywheel energy storage price electrical design]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

Are flywheel energy storage systems a good alternative to electro-chemical batteries?

Electro-chemical ESSs can be used in short-duration services , , but they suffer from a short lifetime and the need to dispose of toxic materials , . Flywheel energy storage systems (FESSs) are a promising alternative to electro-chemical batteries for short-duration support to the grid .

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

How much does a flywheel power converter cost?

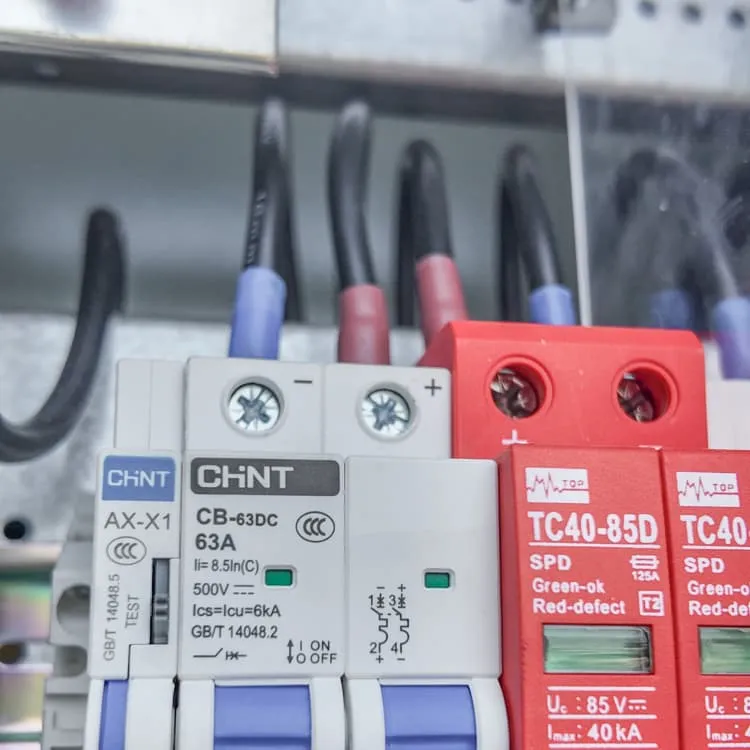

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

More information

- El Salvador s 2025 energy storage order

- Zimbabwe Home Energy Storage System Quote

- Vietnam zinc-bromine flow battery

- Base station wind power supply communication principle

- Canadian 72v lithium inverter

- Norwegian solar energy storage system

- Selling photovoltaic panels

- Export solar systems

- Outdoor solar power generation system energy storage cabinet

- Photovoltaic energy storage 144V battery

- Japanese solar power generation for home use

- Brands of 12V inverters in Northern Cyprus

- Albania Integrated Mobile Energy Storage Power Supply

- Thickness of the battery cabinet

- What are the length and width dimensions of a 630W photovoltaic panel

- Albania lithium battery energy storage prices

- Container power generation design case

- Fiji 5g base station consultation

- Uninterruptible power supply and energy storage battery

- The effectiveness of local energy storage batteries in Colombia

- Multi-function inverter home version

- Power Generation 220 Substation Design

- Communication Green Base Station Installation

- North Korea double glass module processing plant

- PV inverter connection

- Andorra inverter manufacturer